Roller cone bit is indicated by diameter code, series code, IADC classification code and optional feature code.

For example; 8 l/2MD517X

8 112 is bit diameter, indicating the bit diameter is 8.5 inches (215.9mm),

MD is series code, indicating the bit is a high speed motor bit,

517 is classification code, indicating IADC code,

X is optional feature code, indicating the main cutters are convex crested wedge insets.

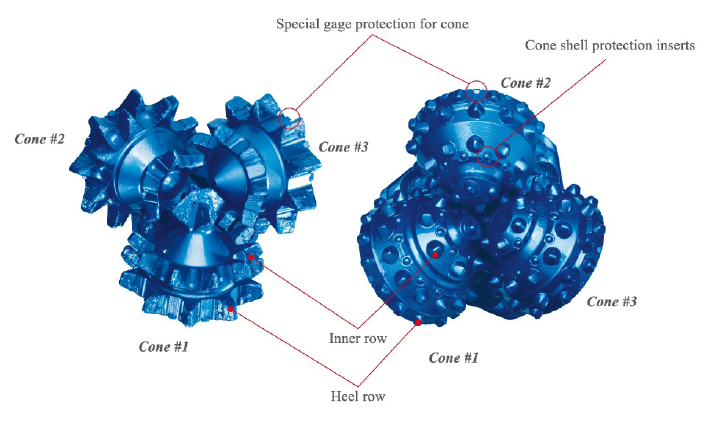

Instruction of roller cone bits structure

OPTIONAL FEATURE

C

Center jet can avoid bit balling, eliminate resorting area of fluid at bottom

hole, expedite upward flow of cuttings and improve ROP. It is suitable for drilling in soft to medium soft formations with low compressive strength and high drill ability.

D

Gage protection by diamond enhanced cutters on head O.D

The gage protection is significantly reinforced by adding diamond enhanced

gage compacts on head On. Bit with (his feature is suitable for drilling in

directional and horizontal well with high abrasive formation.

E

Extended double nozzle.

The hydraulic system of extended double nozzle can expedite upward flow

of cuttings, reduce regrinding of the formation and eliminate resorting area of fluid at bottom hole to achieve effective drilling.

G

Head OD enhancement

Special inserts are strategically arranged on head OD to reduce effectively wear of the head and improve bit’s gage protection in abrasive formation or directional and horizontal wells. Improved gage protection can extend service life of the bit.

H

Gage protection by diamond enhanced cutters on head cone

Diamond compacts armnged in heel row or gage row for the cone can

enhance gage protection and increase its working life. It is suitable for drilling in high abrasive formation, hard or extreme hard formations.

J Directional jet

Directional jet feature (J) enlarges lateral flow area at bottom hole and is helpful to bottom hole cleaning and increase of ROP. Bit with this feature is suitable for soft to medium soft formations of low compressive strength and high drill ability

KCutting structure for hard plastic formation

Unique designing parameters and lengthening insert crest enlarge rock-breaking volume at the bottom hole and increase bottom hole coverage and increase ROP of the bit in hard plastic formation.

L

Head OD stabilization pad

Better protection of bit head and compensating hole can be achieved in directional and horizontal well drilling applications.

There are two types:

1) Bit head OD is reinforced with stabilization pad and compacts;

2)Spherical inserts are used on the lubrication reservoir closely

X Convex crested wedge inserts

Inserts of this shape have high cutting efficiency and anti-rock-breaking ability and can effectively increase bit's ROP and working life .Bit with this feature is suitable for drilling medium soft to medium hard formations.

Y Conical-spherical inserts

If bit is equipped with conical-spherical inserts as main cutting elements, then the bit is suitable for drilling in hard and brittle formations.

|

Bit Size

|

API Regular Pin

|

Recommended make up torque

|

|

Inch

|

mm

|

Inch

|

KN M

|

|

33/4

|

95.3

|

23/8

|

4.1-4.7

|

|

37/8

|

98.4

|

2 3/8

|

4.1-4.7

|

|

41/8

|

104.0

|

23/8

|

4.1-4.7

|

|

41/4

|

108.0

|

23/8

|

4.1-4.7

|

|

41/2

|

114-3

|

23/8

|

4.1-4.7

|

|

45/6

|

117-5

|

27/5

|

6.1 -7.5

|

|

43/4

|

120.7

|

27/6

|

6.1 -7.5

|

|

47/8

|

123.8

|

27/8

|

6.1 -7.5

|

|

51/2

|

139.7

|

3 1/2

|

9.5-12.2

|

|

55/8

|

142.9

|

3 1/2

|

9.5-12.2

|

|

52/3

|

143.9

|

3 1/2

|

9.5-12.2

|

|

53/4

|

146.1

|

3 112

|

9.5-12.2

|

|

57/8

|

149.2

|

3 1/2

|

9.5-12.2

|

|

6

|

152.4

|

3 1/2

|

9.5-12.2

|

|

61/6

|

155.6

|

3 1/2

|

9.5-12.2

|

|

61/4

|

158.8

|

3 1/2

|

9.5-12.2

|

|

61/2

|

165.1

|

3 1/2

|

9.5-12.2

|

|

65/8

|

168.3

|

3 1/2

|

9.5 --12.2

|

|

63/4

|

171.5

|

31/2

|

9.5 -12.2

|

|

71/2

|

190.5

|

41/2

|

163-217

|

|

75/8

|

1931

|

41/2

|

163-217

|

|

77/8

|

200.0

|

4 1/2

|

16.3-21.7

|

|

83/8

|

212.7

|

41/2

|

16.321.7

|

|

81/2

|

215.9

|

41/2

|

16.3-21.7

|

|

85/8

|

219.1

|

41/2

|

16.3—21.7

|

|

83/4

|

222.3

|

4 1/2

|

16.3 -21.7

|

|

91/2

|

241.3

|

65/8

|

38-43.4

|

|

95/8

|

244.5

|

65/8

|

38-43.4

|

|

97/8

|

250.8

|

65/8

|

38-43.4

|

|

10 1/2

|

266.7

|

6 5/8

|

38-43.4

|

|

10 5/8

|

269.9

|

6 5/8

|

38-43.4

|

|

11

|

279.4

|

6 5/8

|

38-43.4

|

|

11 5/8

|

295.3

|

6 5/8

|

38-43.4

|

|

12

|

304.0

|

65/8

|

38-43.4

|

|

121/4

|

311.2

|

65/8

|

38-43.4

|

|

125/16

|

312.7

|

65/8

|

38-43.4

|

|

123/8

|

314.3

|

6 5/8

|

38-43.4

|

|

127/16

|

315.9

|

65/8

|

38-43.4

|

|

125/8

|

320.7

|

65/8

|

38-43.4

|

|

13 1/8

|

333.4

|

6 5/8

|

38-43.4

|

|

13 1/2

|

342.9

|

6 5/8

|

38-43.4

|

|

13 5/8

|

346.1

|

65/8

|

38-43.4

|

|

133/4

|

349.3

|

65/8

|

38-43.4

|

|

14 1/2

|

368.3

|

7 5/8

|

46.1-54.2

|

|

143/4

|

374.7

|

7518

|

46.1-54.2

|

|

151/2

|

393.7

|

75/6

|

46.1-54.2

|

|

16

|

406.4

|

75/8

|

46.1-54.2

|

|

171/2

|

444.5

|

75/B

|

46.1-54.2

|

|

187/0

|

479.4

|

7 5/8

|

46.1-54.2

|

|

20

|

508.0

|

75/8

|

46.1-54.2

|

|

22

|

558.8

|

75/8

|

46.1-54.2

|

|

24

|

609.6

|

75/8

|

46.1-54.2

|

|

26

|

660.4

|

75/8

|

46.1-54.2

|

|